Step 1 -

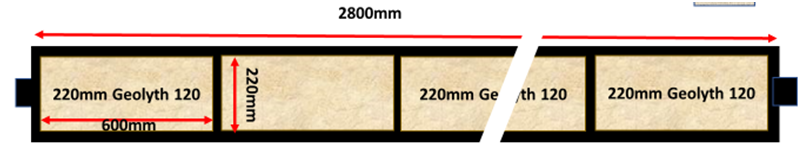

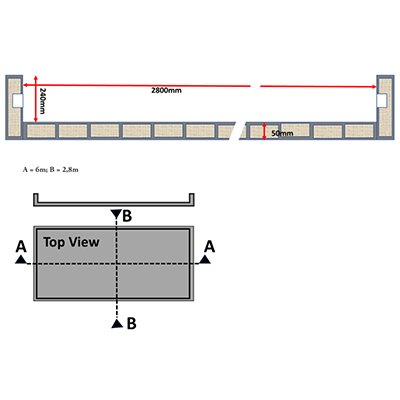

We have a mold in the size of the final element (as an example an exterior wall element in the size of 2,8m x 6m x 290mm).

That mold is stored Each mold has an RFID TAG.

That RFID TAG has all relevant information stored regarding design, raw material to be used, manufacturing process, assembly process and communicated with the appropriate machines and automations

Below - mould with RFID TAG incorporated

Step 2 -

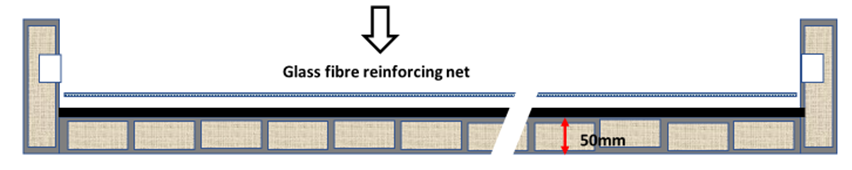

Layering of fiber glass netting

Step 3 -

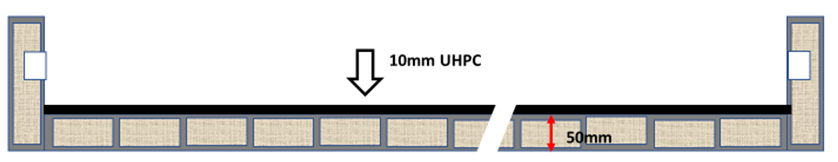

On that element, we cast 10mm of grey UHPC (shown however in black)

Step 4 -

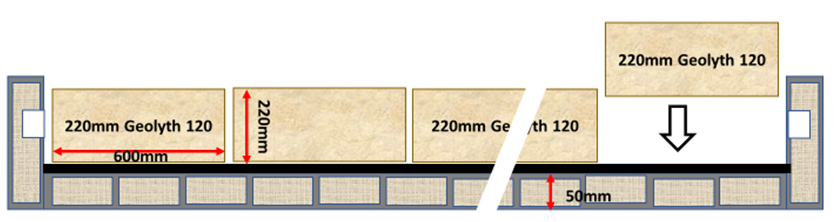

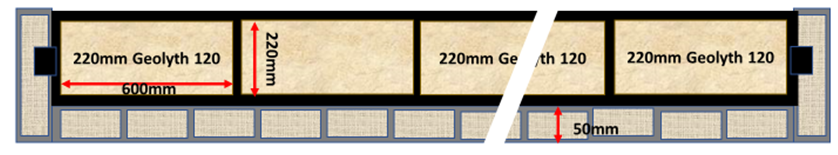

In the still wet UHPC, blocks of mineral foam 120kg/m3 are laid. Between the block a 10mm gap is left. Size of the blocks: 600mm x 600mm x 220mm

Step 5 -

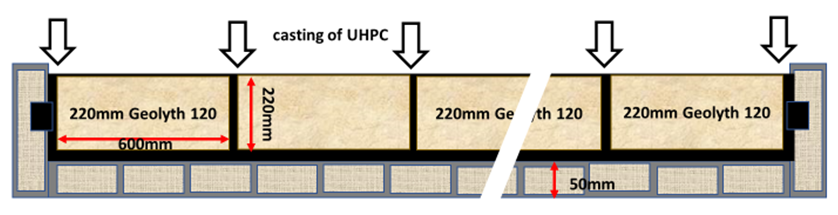

UHPC is cast in the mould. The very fine UHPC is filling the gap and so creating the honeycomb structure. Just enough UHPC is cast to fill the gap

Step 6 -

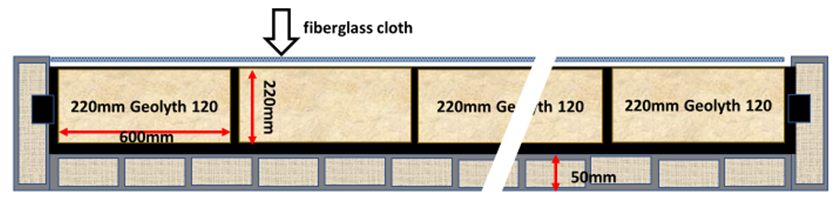

Layers of fiberglass netting is laid.

Step 7 -

10mm UHPC is cast to create a deck

Step 8 -

After 24-hour hydration (ripening) in a climatized chamber, the element is taken out of the mould